Process and production capacity

INTERNAL PRODUCTION PROCESSES

CNC PROCESSING

Fanuc Robodrill with ALPHA D21-LiB5 10k/10,000 rpm spindle with 4 axes for milling, drilling and threading operations.

Haas VF-2SSYT-EU 4-axis milling cutter for high-speed milling operations.

SURFACE PROCESSING

Arcos/Fanuc robot island for polishing, grinding, satin-finishing and brushing operations.

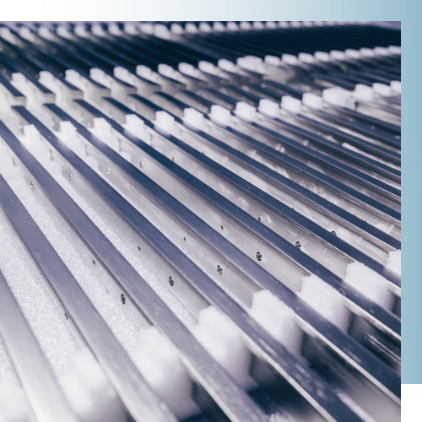

LAMPUGNANI LC 2TR glass / ceramic / corundum sandblasting machine.

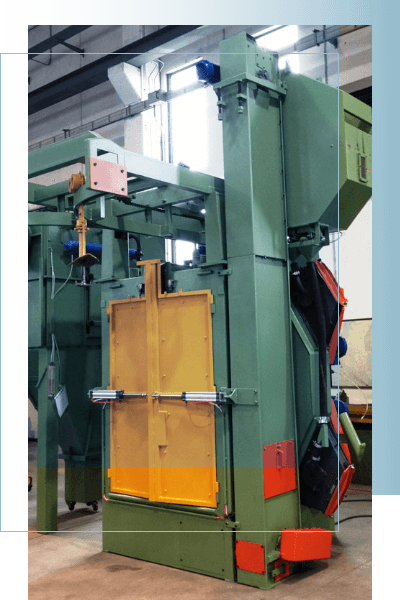

Carlo Banfi mod. GM 9×14 shot peening machine.

Milling department

WELDING AREA

C.M.B. can boast a welding area consisting of three Siegmund workbenches: a tacker, a positioner and a flexible clamping system. We can weld iron, stainless steel and aluminium.

OMRON COLLABORATIVE ROBOT MOD. TM12

Collaborative robot for welding operations.

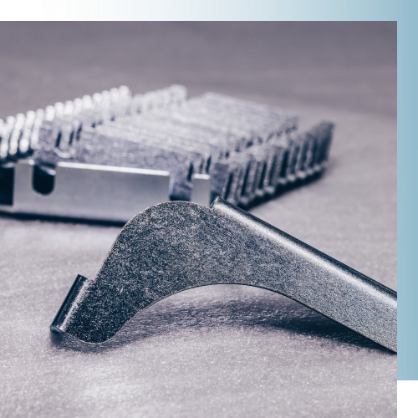

WELD STUD FASTENING DEPARTMENT

Weld studs are high-strength fastening and joining elements that ensure a high level of tightness in a variety of professional contexts. All is done in-house.

MECHANICAL AND ELECTROMECHANICAL ASSEMBLIES

C.M.B. guarantees the possibility of manufacturing complete electromechanical subassemblies, including mechanical parts, electronic boards, cables, motor and external housing. We can also arrange for a final functional test to be performed on the finished product before shipment, depending on the customer’s analysis procedures and testing equipment.

THERMOMECHANICAL GL MOD. SEMI DOWN DRAFT BOOTH

Spray booth for spraying water- or solvent-based paints.

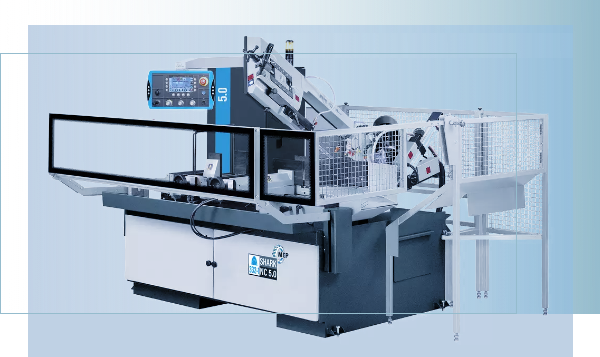

SHARK 332-1 NC 5.0 SAW

Automatic band sawing machine for cutting metals from -45° to +60° (also angular). In addition to the automatic cutting cycle, it is also equipped with the semi-automatic, dynamic semi-automatic and manual cycle.

GMR MOD. 325 PRESS

Two-post hydraulic press for pressing pins.

EXTERNAL PRODUCTION PROCESSES

SURFACE TREATMENTS THROUGH APPROVED PARTNERS

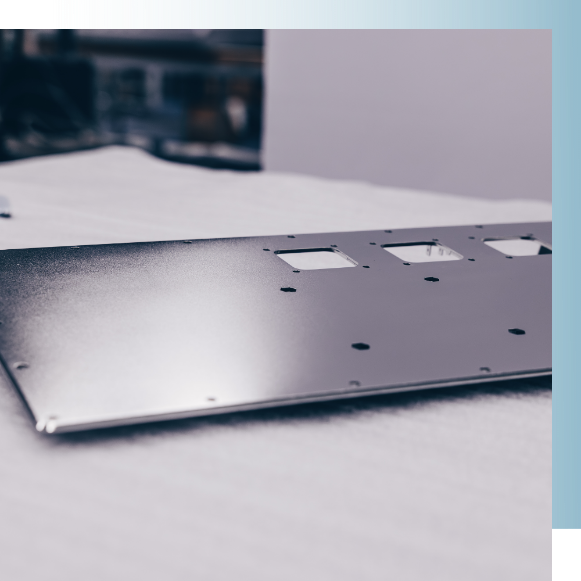

C.M.B. has a wide network of established partners to ensure various surface treatments to its products, such as powder coating, nickel plating, anodising, carburizing, electropolishing and many more.

Nickel-plated parts

Zinc-plated parts

Cataphoresis parts

Painted parts

Anodised parts

Electro-polished parts

Phosphating parts